Without streamlined procurement contract management, organizations face contract value erosion averaging 9% of annual revenues—approximately $2.5 trillion globally, according to McKinsey research. For procurement teams managing supplier relationships worth millions, this represents a critical operational and financial risk.

Let’s dive into everything you need to know about procurement contracts and how to manage them better.

What is a procurement contract?

A procurement contract, also called a purchase contract, is a legally binding agreement between a buyer and a seller. It formalizes the procurement process and establishes the foundation of buyer-seller relationships by clearly outlining what each party expects from the other.

Procurement contracts establish clear parameters—from the quality of materials to when they’ll be delivered and how much you’ll pay. Procurement contracts are how businesses outsource work to vendors who can get the job done without breaking the bank.

One of the primary functions of procurement contracts is to minimize risks. These agreements mitigate risk through clearly defined rights, responsibilities, and performance obligations.

By putting these elements in writing, both parties have clear expectations, help you manage third-party risks better, and offer coherent legal recourse if those expectations aren’t met.

The cost of poor procurement contract management

The financial impact of inadequate vendor contract management extends beyond immediate costs. Based on World Commerce and Contracting data, the average expense for drafting and finalizing even a low-risk contract reaches $6,900. However, the real cost emerges post-signature:

Cost overruns:

- Unchecked consumption against contract terms

- Unclaimed credits and negotiated discounts

- Scope creep without corresponding price adjustments

Manual obligation tracking challenges:

- Unclear accountabilities across departments

- Scattered contract storage prevents performance visibility

- Missed renegotiation opportunities due to poor data access

When mistakes slip through to the payment stage, it results in you being legally obligated to honor the signed contract.

What is the significance of procurement contracts?

Procurement contracts serve as documents of trust, risk management, and clarity in business relationships. Their importance extends across several critical areas:

Ensuring trust and accountability

Businesses often work with partners they’ve never met in person. Procurement contracts establish reliability by creating formal accountability mechanisms that both the buyer and seller must honor.

Protecting rights and obligations

A well-drafted procurement contract protects both buyers and sellers by clearly outlining their rights and obligations. This clarity prevents misunderstandings and ensures each party knows exactly what they’re responsible for delivering.

Monitoring vendor performance

Contracts provide the framework for evaluating vendor efficiency and relationship quality. By establishing clear performance metrics, organizations can objectively assess whether vendors are meeting their obligations.

Legal compliance and risk mitigation

They make sure you stay compliant with governing laws and policies and offer legal protection in scenarios of third-party risks, contract termination, legal dispute, operational delay, and financial loss.

According to procurement leadership research, 88% of organizations cite integration issues as their primary challenge when implementing new contract management processes. Outside the frameworks of a well-thought-out contract and robust contract management processes, these challenges may be harder to navigate.

Key components of a procurement contract

An effective procurement contract includes several essential components:

1. Buyer and seller details

- Identification of parties involved: Every contract needs to spell out who’s involved in the agreement. This includes legal business names, addresses, and decision-making stakeholders who have the authority to sign on behalf of each organization.

- Legal obligations and responsibilities: The agreement specifies the obligations of each stakeholder and penalties in case these obligations are missed.

2. Scope of work

- Description of goods or services provided: This section lists out exactly what the seller intends to provide specifically with little room for misinterpretation.

- Specific quality standards and parameters: This section explicitly states the quality expectations, industry standards, and certification criteria.

3. Pricing and payment terms

- Fixed vs. variable pricing models: Procurement contracts should specify whether prices are fixed for a specific period or vary based on determined factors.

- Payment terms, schedules, methods, and penalties: Here, the contract outlines when and how payments should be made and provisions like penalties for late payments and discounts for early payments.

4. Delivery terms

- Timelines and schedules: This section maps out delivery expectations, including specific dates and timeframes for when goods and services will be delivered.

- Inspection and acceptance process: The contract also includes how delivered goods and services will be inspected and what makes constitutes a formal acceptance by the buyer.

5. Performance monitoring and compliance

- Key performance indicators (KPIs): These metrics will objectively measure supplier performance (delivery times, quality rates, etc).

- Compliance: Explicitly requiring adherence to relevant laws like GDPR protects your organization from liability.

6. Dispute resolution and termination clauses

- Conflict resolution: Specifying a clear escalation path (mediation → arbitration → litigation) can save significant time and money.

- Contract cancellation conditions: Clearly defined exit conditions protect both parties and prevent being locked into problematic arrangements.

What are the types of procurement contracts?

Procurement contracts need to be structured differently for different scenarios. The following are most commonly used.

1. Fixed price contract

Fixed price contracts, also called lump-sum contracts, set clear project terms, key payment dates, and establish what goods or services will be delivered, when, and what price the buyer pays. It also defines responsibilities and is the most common type of contract in supplier relationships.

When to use fixed-price contracts?

Fixed price contracts work best when you know exactly:

- Requirements are unlikely to change and can be clearly defined

- The market is predictable

- The scope of work is understood by both parties properly

- The buyer anticipates to spend sustainably without cost overruns

Subtypes of fixed-price contracts

Firm fixed price (FFP): In this arrangement, the price remains unchanged throughout the contract. The buyer and supplier agree that the buyer will make a minimum order and the seller will provide the goods and services at a specific cost.

Fixed price & incentive fee (FPIF): This contract stipulates that the buyer will pay a fixed fee for the minimum order amount of supplies plus incentive should the supplier meet and exceed terms of the contract. As a form of performance-based agreement, additional compensation for performance may be incentivized.

Fixed price with economic price adjustment (FPEPA): In this model, the buyer and supplier are locked in agreement for a certain volume of supplies. If the costs of production increase, the supplier adjusts prices to protect their margins.

Fixed price procurement contracts with economic price adjustment are particularly useful in long-term contracts where the market conditions are anticipated to fluctuate significantly.

Example

These contracts are best used when you’re buying inventory or office supplies for a specific price or when you’re building standardized aircrafts.

55% of procurement leaders prioritize improving speed-to-value and ROI.

Fixed price contracts support this objective by providing cost predictability that enables accurate budget forecasting and resource allocation.

2. Cost-reimbursement contracts

In cost reimbursable contracts, the buyer agrees to pay for the actual costs incurred for materials and equipment and indirect or production costs such as salaries and utilities. The seller provides an optimum price for the buyer—as long as the buyer follows through with minimum order.

When to use cost-reimbursement contracts

Cost reimbursement contracts are best used when you’re ready to pay for what it costs, plus some extra. They are best suited for the following scenarios:

- The project scope is uncertain and subject to change

- Costs are difficult to estimate accurately in advance

- The project involves significant research and development

- The buyer expects maximum flexibility

Examples

These contracts are used in projects with high uncertainty, like when developing a new drug or building a prototype

GenAI capabilities are already being deployed across the procurement value chain, and companies are seeing immediate impact. They directly interact with suppliers at double the speed:

• Eliminate 90% spend on manual data analysis

• ~ 15% savings potential on vendor tool selection

• ~85% time savings when writing supplier letters

Subtypes of cost-reimbursement contracts

Cost plus fixed fee (CPFF): The seller sends product, service, or project costs with specified quantity and quality. After completion, the seller is reimbursed for incurred expenses plus a fixed bonus, which is usually a percentage of the overall figure. If delivery is unsuccessful, the buyer typically reimburses costs, so the seller wouldn’t bear losses unless agreed upon details explicitly state it.

Cost plus incentive fee (CPIF): This contract is similar to CPFF, but includes reimbursement plus an incentive for meeting specific targets. If unsuccessful, buyer and seller split the cost, encouraging both parties to work toward success.

Cost plus award fee (CPAF): This contract is designed so that the seller provides goods and services as agreed with the buyer. The supplier is reimbursed for costs and receives an award fee at the buyer’s discretion, typically based on the qualitative evaluation of performance.

3. Time and materials contracts

In time and materials contracts, the supplier is reimbursed for the materials used and the time spent. It functions like a third-party purchasing agreement and is often used for services where the exact scope is difficult to define upfront.

When to use time and materials contracts

Time and materials contracts are appropriate when you intend to pay the supplier for the time and materials used. Best used when:

- The full scope of work cannot be accurately estimated

- The project may evolve and need flexibility

- Work needs to start before the full scope of work is specified

- Services required are for a specific period without defined contract deliverables

Examples

You hire a software developer for a short-term project, get an emergency repair on machine parts, or hire a consultant for an undefined project.

From bottleneck to strategic advantage

Ready to see the difference that purpose-built contract management can make? Let’s talk.

Best practices for procurement contract management

Managing procurement contracts can be difficult if there are no right systems in place. Here are some battle-tested practices that can make your contract management reliable, secure, and efficient.

ProcureCon CPO Report reveals that supplier and contract management teams spend 80% of their time on data management, reporting, compliance, and risk management, with only 5% dedicated to strategic activities.

Get crystal clear on expectations

Some of the biggest contract failures can be traced back to unclear expectations. Research indicates that 46% of procurement leaders consider reducing operational costs a high priority. Achieving this requires moving beyond subjective assessments to quantifiable performance indicators. Define specific metrics for delivery accuracy, quality standards, and response times that can be tracked and reported automatically.

Track performance rigorously

You can’t improve what you don’t measure, especially when your business depends on it. You can track performance on spreadsheets or use automated dashboards with supplier delivery timeframes against contractual obligations, automated alerts, and periodic reviews with data-backed insights.

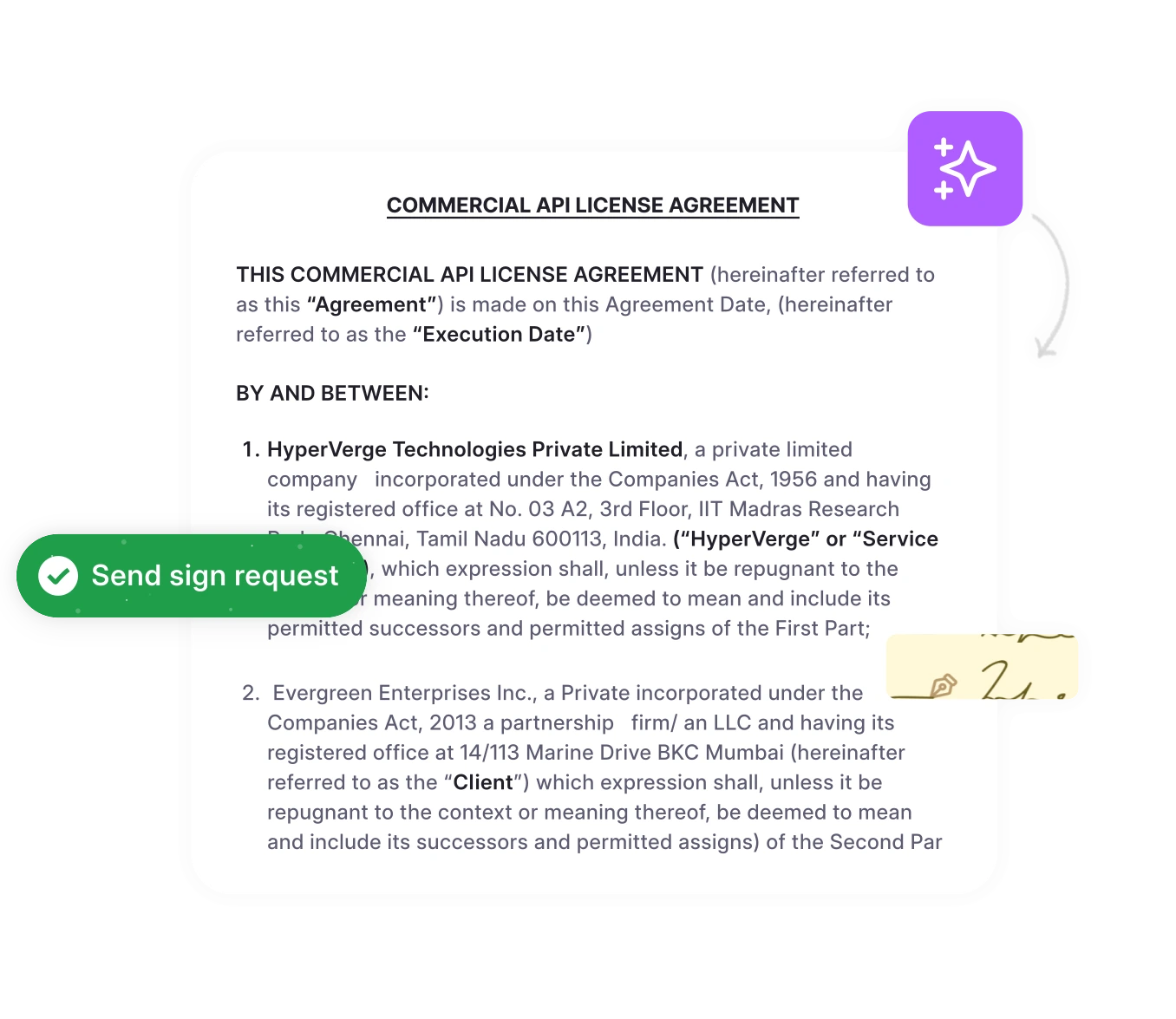

Implement a CLM

Contract management software automates repetitive tasks like manual renewal tracking, approval routing, contract signing, and process tracking. They are anchored in a central repository that organizes and locates the contract data you need in seconds and also helps you stay audit-ready. Drillable dashboards help you track key metadata and improve performance. They extract key metadata with AI and analyze it for key obligations, payment terms, schedules, liabilities, and indemnities. Implementing your CLM may take anywhere between 1 week to a few months.

How HyperStart simplifies procurement contract management

HyperStart contract lifecycle management system is built from the ground up with feedback from hundreds of legal experts. We’ve watched pain points, understood workflows, and our proprietary AI has proven 95% accuracy across 1 billion documents. HyperStart CLM helps your team:

- Bring all your contracts into one searchable, accessible home in a central repository. No more context switching across shared drives and email attachments.

- Automate mind-numbing approval workflows. The average contract approval time drops from days and weeks to a few hours.

- Stay on top of key milestones and dates. Track metrics that actually matter to your business. Never miss a renewal or obligation again.

- Generate reports that your leadership actually needs to make the right decisions.

- Collaborate with all your vendors in a central, secure environment. No more broken systems and endless email chains.

Procurement leadership requires balancing operational efficiency with strategic value creation. As procurement teams face increasing pressure to drive value beyond cost savings while managing complex supplier relationships, the choice of contract management platform becomes critical to organizational success.

If procurement tracks renewal dates in a spreadsheet and vendor contract is not recorded, the business requester would come to them saying: “Hey, my contract is expired. I want to negotiate new terms.”

But, because you had been cut off from the product after the contract expired, you lose your negotiation position. You’d end up with bad terms and the highest price because the vendor wouldn’t negotiate.

De-bottleneck procurement contracts

Ready to see the difference that purpose-built contract management can make? Go from bottleneck to strategic advantage. Let’s talk.

Book a Demo